System Features

The design technology of turbine expander is more mature.

Distributed design, single machine can achieve small power to high power arbitrary design.

Unit cost is low, and the cost of single high-power machine is relatively low compared with that of many parallel small units.

|

Condensate waste heat power generation project of a coal chemical enterprise

|

|

The technical transformation project added a 3.3MW condensing saturated steam turbine power generation system.

|

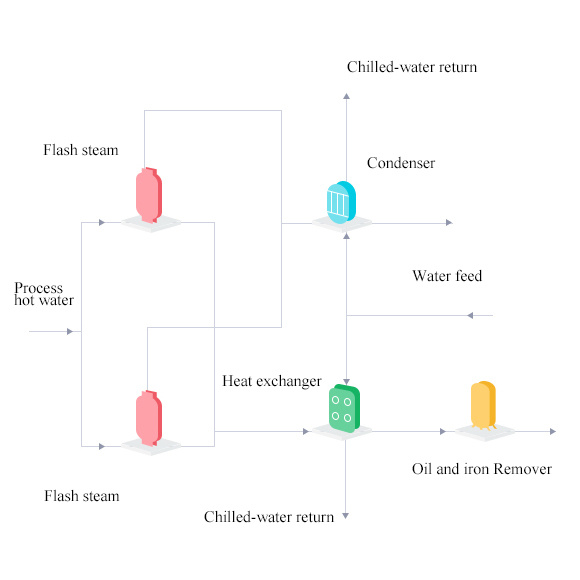

Project Process Drawing

Heat source process flow chart

Waste heat power generation system PFD

Retrofit Scheme

Nozzle group and separator, regulating stage sheath

The nozzle is of assembly welded type or band welded type structure. It is bolted to the cylinder nozzle chamber. The lower half partition board is supported on the two suspension pins at the split face of the cylinder, and the bottom is provided with a certain position key with the cylinder, and the upper and lower partition board is provided with a sealing key and a positioning pin at the middle split face. The adjustable stage sheath is supported on the cylinder by a "hanging ear" structure with positioning screws on both sides of the hanging ear.

Cylinder

It has a vertical and horizontal center section, and can not be disassembled after the front and rear cylinders are connected. The steam chamber is welded to the front cylinder. The new steam enters the cylinder through the main valve, and the exhaust port of the rear cylinder is rigidly connected with the condenser. The front cylinder and the front bearing seat are connected by "lower cat claw", and the rear cylinder is supported on the rear seat frame by the side support feet on both sides, and there is a horizontal sliding pin between the support feet and the rear seat frame. The center of the transverse slide pin forms the dead point of the cylinder thermal expansion with the center of the longitudinal slide pin of the rear bearing seat and the front seat frame.

Bearing

The front bearing and thrust bearing of the turbine are composed of spherical combined bearings. The thrust bearing is of swing tile type. When the diameter of the current bearing is ≥φ180mm, an adjusting needle valve is provided at the oil return of the thrust bearing, which can be adjusted according to the oil return temperature. The front and rear radial bearings are elliptical bearings. The main push block and the lower half bearing of the radial bearing are equipped with platinum thermal resistance.

Main valve and main valve control seat

The main valve is a single seat stop valve. The control seat is hydraulic. The pressure oil is controlled by a security device. When the security device is suspended, the security oil flow enters the control seat cylinder and pushes the piston to move, and the main valve can be opened. When the security device is operated, the security oil pressure is rapidly reduced, but the oil pressure in the control seat is quickly discharged under the action of the spring force, and the oil in the cylinder is quickly closed.

Regulating steam valve and connecting rod

It is a group valve lifting plate structure. When the load changes, each valve disc is opened in a certain order. Disc travel, factory-adjusted.

Live Photo

Project Site

Project Site

Project Site

Official account

Xi 'an city:5th Floor, Building B, Jinpan (Tower),

Fengcheng 9th Road, Weiyang District, Xi'an City

Tel:+86 029-89190101

Ningbo city: No. 505 Dinghai Road, Zhaobaoshan Street, Zhenhai District

Tel: +86 18969840090

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.