System Features

The design technology of turbine expander is mature.

Unit special focus design, for steam containing ash heat source, stator and rotor have special design to ensure the normal operation of equipment in production.

Special sealing is required, and the stability of the sealing determines the stable operation of the unit, which requires real-time monitoring and regular maintenance of the sealing.

|

Coal chemical enterprise gasification unit true flash steam waste heat power generation project

|

|

According to the site situation, the content of technical reform is:

The technical transformation project added two sets of installed power of 2×1MW low-parameter ash steam heat source turbine expansion power generation system.

|

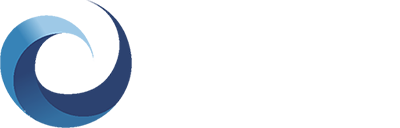

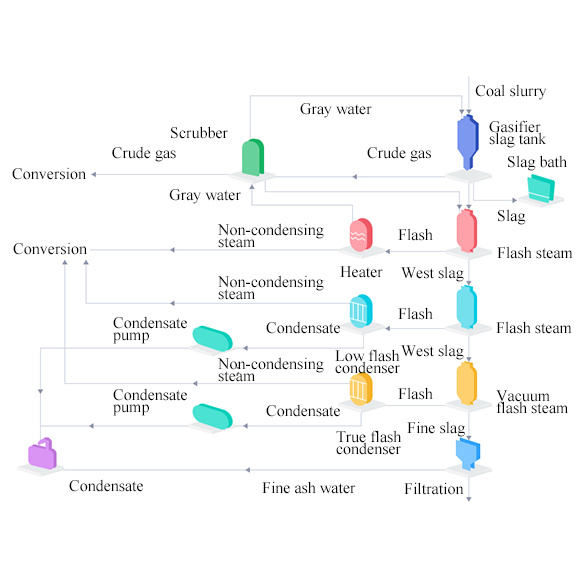

Project Process Drawing

Heat source process flow chart

Waste heat power generation system PFD

Retrofit Scheme

Host characteristics

Boomtec using the characteristics of advanced turbine technology, parametric design is adopted on the rotor, and detailed modular design is adopted for different positions. Compared with the traditional blade profile, Boomtec’s proprietary technology is used to transform the blade parts, and the enthalpy drop is small and the secondary flow is significantly weakened. At the same time, the blade profile has a wide adaptation range of angle of attack, and the unit's variable load operation economy is improved. The final long blade is a full-circle self-locking and damped torsional long blade with low dynamic stress, and the static blade is a bent and twisted blade with good aerodynamic performance. Steam seals and water seals are added to the tip of the turbine blade and the shaft to prevent air leakage and reduce heat consumption.

Condenser design features are introduced

Shell and tube heat exchangers are used in the condenser of the system, and 316L stainless steel tubes are used in the heat exchange tubes. The ash-containing steam is condensed through the shell side, and the 316L stainless steel tubes have strong corrosion resistance.

Water ring vacuum pump introduction

The selected water ring vacuum pump in the system ensures the normal operation of the vacuum state. The water ring vacuum pump has the advantages of simple structure, low manufacturing precision and easy processing. Compact structure, high pump speed, generally can be directly connected with the motor, no deceleration device. Therefore, with a small structure size, you can obtain a large displacement and occupy a small area.

The compressed gas is basically isothermal, that is, the temperature of the compressed gas process changes very little. Because of no metal friction surface in the pump chamber, there is no need to lubricate the pump, and the wear is very small. The sealing between the rotating part and the fixed part can be done directly by the water seal. The suction is uniform, the work is stable and reliable, the operation is simple, the maintenance is convenient.

Condensate pump selection introduction

The condensate pump adopts variable frequency pump, which can adjust the output of the condensate pump according to the system load, saving energy and reducing consumption.

Layout introduction

All the equipment in the system is arranged in the form of double-layer steel structure. The low-parameter ash-containing steam heat source turbine expansion generator set is arranged on the upper level, the system valve, condenser, water ring vacuum pump, condensate pump and other centralized layout on the platform, the steel component is placed in the outdoor, the floor area, the arrangement of the equipment, the connection of the pipes and valves between them are comprehensively considered, the pursuit of higher efficiency.

This section describes the cold source mode

Circulating cooling water is used to cool the ash-bearing steam. Similar projects can also choose evaporative condenser, water-cooled and air-cooled forms as cold sources according to the characteristics of the site.

Live Photo

Official account

Xi 'an city:5th Floor, Building B, Jinpan (Tower),

Fengcheng 9th Road, Weiyang District, Xi'an City

Tel:+86 029-89190101

Ningbo city: No. 505 Dinghai Road, Zhaobaoshan Street, Zhenhai District

Tel: +86 18969840090

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.