System Features

Modular integration technology. Turbine and generator integrated design, the generator is a high-speed rare earth permanent magnet, the shell is a shield, no working fluid leakage point, small operation and less maintenance.

Use of multi-point control of the active magnetic bearing, stationary and rotating parts without physical contact, the whole process without wear, no lubrication, so that the rotor can run at high speed.

Maglev unit adapts automatically with the change of heat source, and always maintains high efficiency operation by changing the speed, and the system's performance is obviously higher than that of the conventional speed unit.

|

Esterified steam ORC waste heat power generation project in chemical fiber industry

|

|

According to the site situation, the content of technical reform is:

Two sets of 650kW maglev integrated ORC turbine power generation systems were added

|

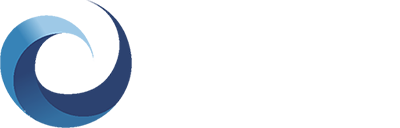

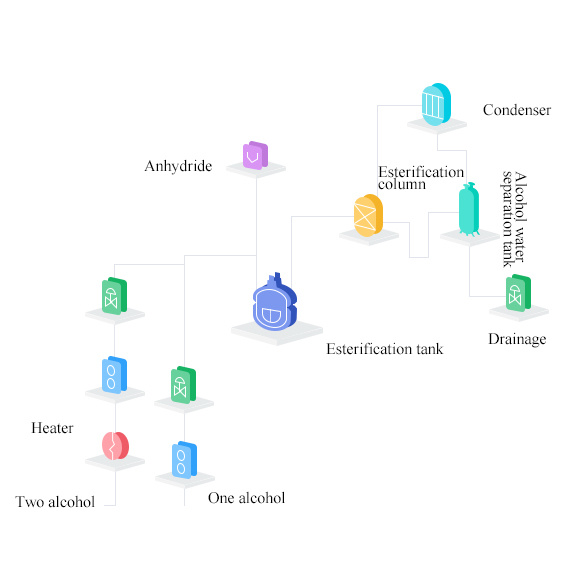

Project Process Drawing

Heat source process flow chart

Waste heat power generation PFD

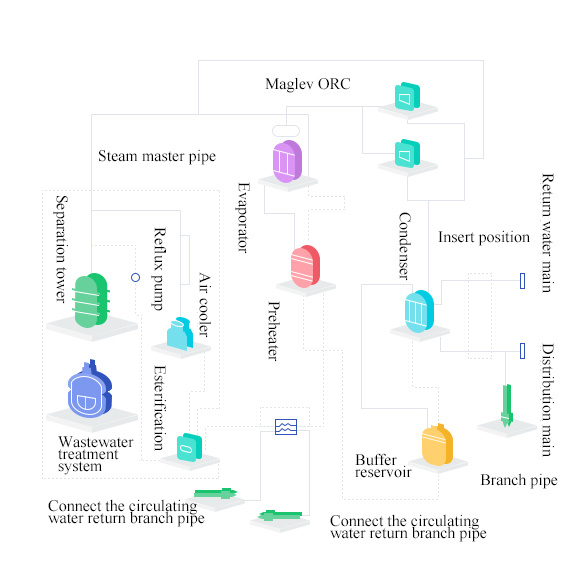

Retrofit Scheme

Host characteristics

Using the shield integrated ORC turbine generator developed and designed by Boomtec, the unit adopts an integrated design, integrating turbomachinology, permanent magnet synchronous generator and magnetic levitation technology, which is a highly integrated mechatronics product to ensure that the working medium has no leakage, long life, low noise and high efficiency.

The turbine part adopts efficient radial turbine, and the turbine adopts CN software calculation design, and the whole milling of five-axis machining center. A guide vane adjustable device is designed at the front end of the turbine, which is used to adjust the working condition to adapt to the change of heat source. Volute using cast steel 25 casting molding, smooth flow path, beautiful appearance. The motor shell is also made of cast steel and connected with the volute with a flange. There is a cooling grid in the motor shell, and the low-temperature gaseous working medium flows through the cooling grid to cool the stator, rotor and magnetic bearing of the generator. The gaseous working medium after cooling the motor enters the condenser through the pipe and condenses into liquid state.

Features of cold source mode

Circulating cooling water is used to cool the organic working medium steam exhaust. Similar projects can also choose evaporative condenser, water-cooled and air-cooled forms as cold sources according to the characteristics of the site.

Unit layout

All the equipment in the system is arranged in the form of single-layer steel structure. Evaporator, preheater, working medium pump, ORC turbine expansion generator set, system valve, condenser, liquid storage tank, centralized layout on the platform, this steel component is placed in the outdoor, the floor area, the arrangement of the equipment, the connection of the pipes between them, the valve are comprehensively considered, the pursuit of higher efficiency.

Working medium pump selection introduction

The working medium pump adopts a shielded variable frequency pump, which can prevent the leakage of organic working medium, and the variable frequency pump can adjust the output of the working medium pump according to the system load to ensure the smooth operation of the system.

Condenser design features

Tube-and-shell heat exchanger is used in the condenser, and TP2 copper tube is used in the heat exchange tube. The organic working fluid is condensed through the shell side, and the copper tube has good heat transfer performance.

Evaporator, preheater design features

The evaporator and preheater in the system use shell and tube heat exchangers. Because the esterified steam contains corrosive substances, 316L stainless steel is used in the evaporator and preheater of the esterified steam ORC to prevent corrosion. The esterification steam contains a small amount of non-condensing steam, and the heat exchangers are equipped with vent valves to discharge non-condensing steam.

Live Photo

Side view of the unit

Unit front real picture

Official account

Xi 'an city:5th Floor, Building B, Jinpan (Tower),

Fengcheng 9th Road, Weiyang District, Xi'an City

Tel:+86 029-89190101

Ningbo city: No. 505 Dinghai Road, Zhaobaoshan Street, Zhenhai District

Tel: +86 18969840090

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.