Appreciation of Typical Cases of Esterification Steam Waste Heat Utilization

At present, the abundant waste heat resources generated in the industrial production process in our country generally have low utilization rates and huge waste. Boomtec New Energy closely follows the development direction of national strategic emerging industries and vigorously develops key core technologies such as resource recovery and recycling. Two mature process packages have been developed and successfully applied for the utilization of polyester waste heat generated in the production process of the chemical fiber industry. In the two polyester waste heat utilization projects of Boomtec New Energy, a chemical fiber enterprise with an annual spinning capacity of 250000 tons used for the first time the independently developed national high-end equipment manufacturing key field first (set) product -650kW ORC integrated magnetic levitation permanent magnet synchronous turbine expansion generator set. This unit is currently the largest single machine power magnetic levitation permanent magnet synchronous integrated generator in China and even the world, filling the domestic gap!

Release time:

2024-04-26

At present, the abundant waste heat resources generated in the industrial production process in our country generally have low utilization rates and huge waste. Boomtec New Energy closely follows the development direction of national strategic emerging industries and vigorously develops key core technologies such as resource recovery and recycling. Two mature process packages have been developed and successfully applied for the utilization of polyester waste heat generated in the production process of the chemical fiber industry. In the two polyester waste heat utilization projects of Boomtec New Energy, a chemical fiber enterprise with an annual spinning capacity of 250000 tons used for the first time the independently developed national high-end equipment manufacturing key field first (set) product -650kW ORC integrated magnetic levitation permanent magnet synchronous turbine expansion generator set. This unit is currently the largest single machine power magnetic levitation permanent magnet synchronous integrated generator in China and even the world, filling the domestic gap!

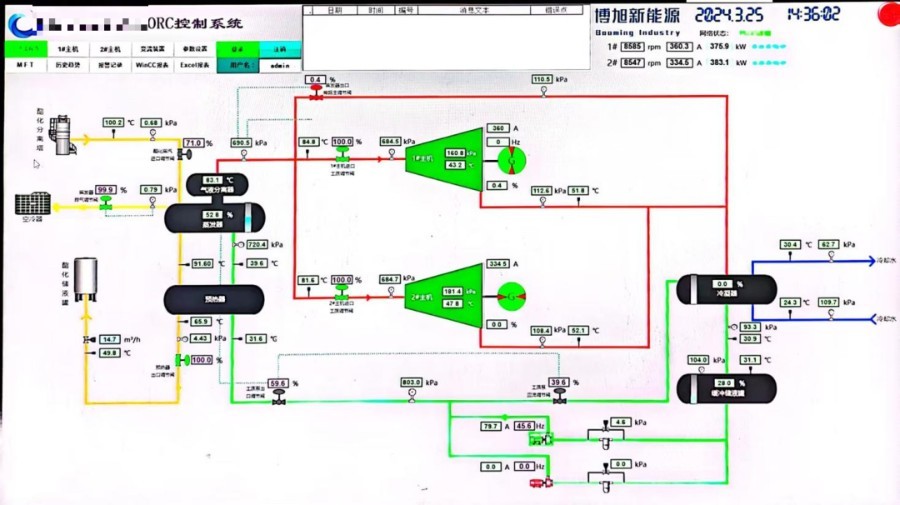

Introduction to the first product -650kW ORC integrated magnetic levitation permanent magnet synchronous turbine expansion generator set

A chemical fiber enterprise with an annual spinning capacity of 250000 tons uses traditional processes such as air cooling island cooling to generate esterification steam during the esterification stage of PET synthesis process, which requires additional electricity consumption. This project is the first to use Boomtec New Energy's first national product, the shielded ORC turbine generator system. The system adopts an integrated design, integrating turbine machinery, permanent magnet synchronous generator, and magnetic levitation technology. It is a highly integrated electromechanical product with advantages such as zero leakage of working medium, long service life, low noise, and high efficiency.

Live shooting of the project site

The installed capacity of this project is 650kW dual unit operation. It has been put into operation and has achieved long-term stable power generation. It can achieve a saturated steam gross power generation power of 50-60 kWh/ton at 100 ℃, reaching the leading level in the same process segment of the industry, with considerable economic benefits.

2*650kw

Dual unit operation interface

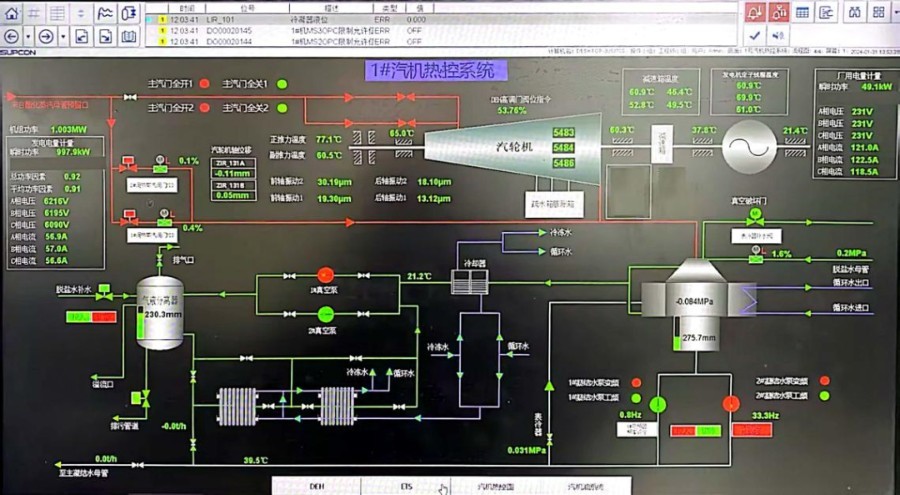

Case introduction of esterification steam direct drive turbine generator set

A chemical fiber enterprise is constructing a 500000 ton/year food grade PET polymer new material project. Boomtec New Energy adopts advanced turbine technology to utilize the esterification steam in the production process, and all the generated energy is used for project production. This project adopts a new mature low parameter waste heat recovery and utilization system as well as turbine expander design technology.

This unit has been specially designed with a focus on the characteristics of esterification steam. It has a customized all stainless steel body, and the turbine stator and rotor are specially designed to ensure long-term stable operation of the equipment. Due to the presence of a small amount of non condensable gas in the esterification steam, an aftercooler is added to the vacuum pumping system to ensure stable vacuum operation of the steam turbine system.

Live shooting of the project site

The project has an installed capacity of 1.6MW and has been successfully put into operation for power generation. It can achieve a power generation capacity of 60-70 kWh/ton of saturated steam at 100 ℃, with considerable economic benefits.

1.6MWe

Unit operation interface

At present, there are still many problems in China's energy utilization, such as low utilization rate, poor economic benefits, and high ecological environment pressure. Energy conservation and emission reduction, reducing energy consumption, and improving comprehensive energy utilization rate are important contents of energy development strategic planning, and are the fundamental ways to solve China's energy problems.

Key words:

follows,direction,technologies

Previous article

Related News

Share